Industrial passivation

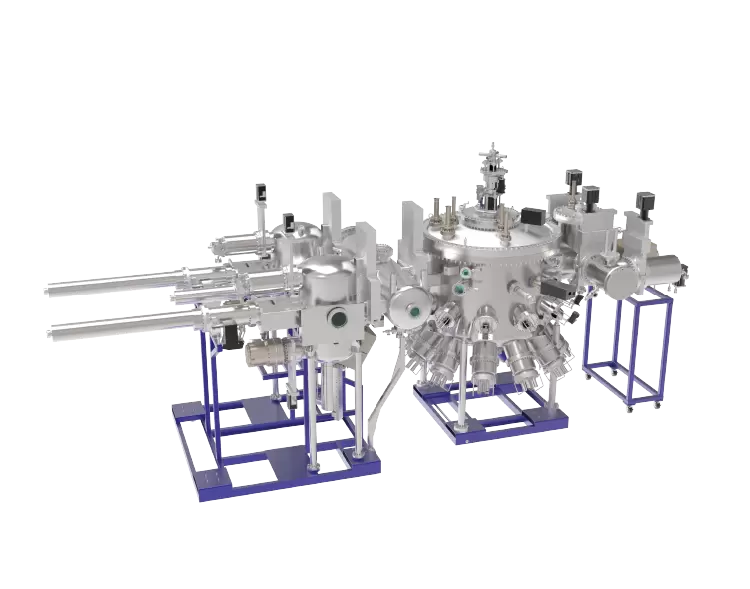

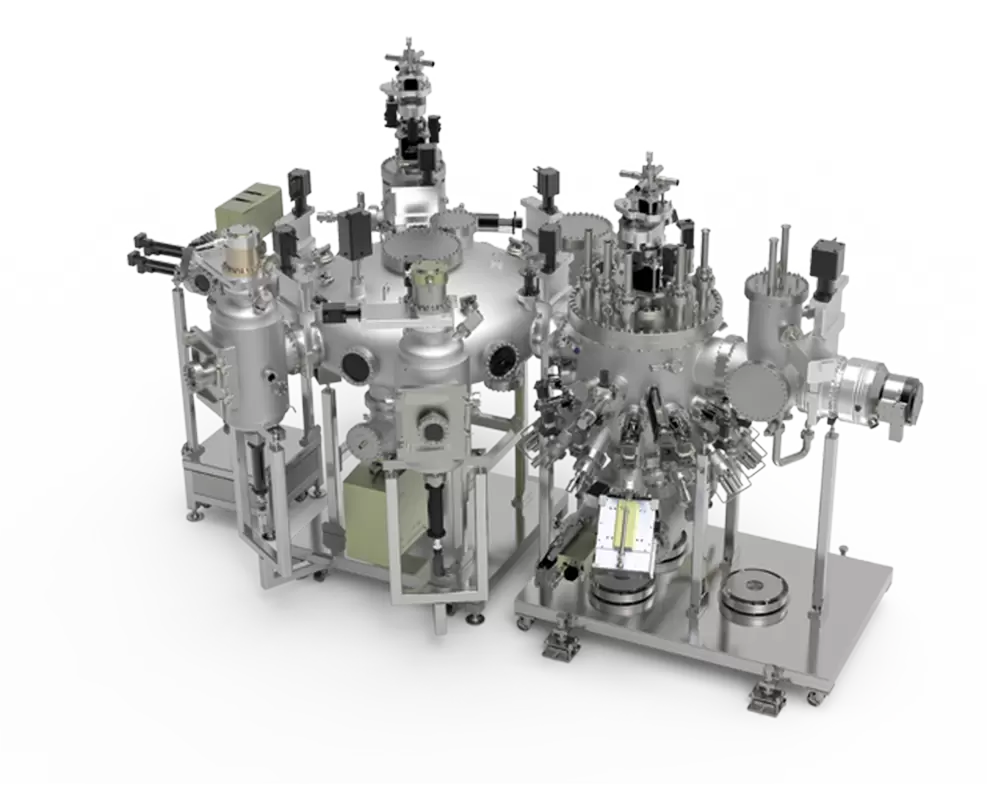

The vacuum cleavage coating system can realize ultra-high vacuum in-situ cleavage (Cleaving), passivation (Passivation) and optical coating (Optical Coating) of high-power laser bars. In-situ cleavage of laser diode bars in an ultra-high vacuum environment can obtain defect-free and pollution-free single crystal cleavage surfaces. The cleaved bars are transferred to the coating chamber through a circular transfer chamber (Cluster Tool) for passivation film or optical film evaporation. The entire process is carried out in an ultra-high vacuum environment better than 2*E-10 torr to achieve high-quality device production.

Plasma

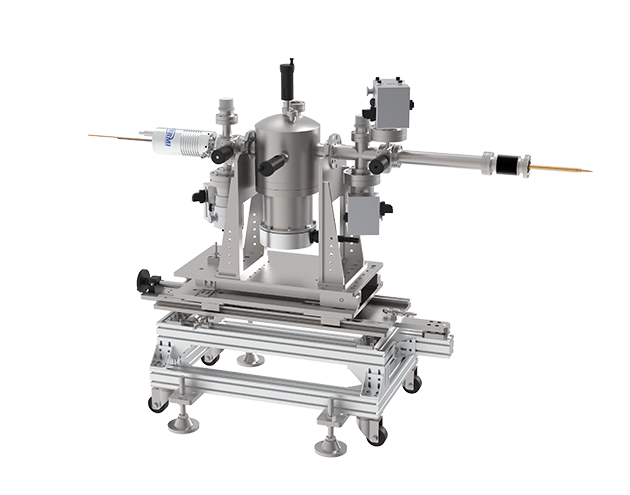

Fermion BL-1100S is a specially designed high-brightness multi-gas mixed vacuum ultraviolet light source, which includes a differential cavity, a monochromatic cavity, and a gate valve that isolates the focusing capillary from the differential cavity. It can use a variety of working gases (He, Xe) to meet the requirements of small light spot and small gas pressure increment.

R&D Instruments

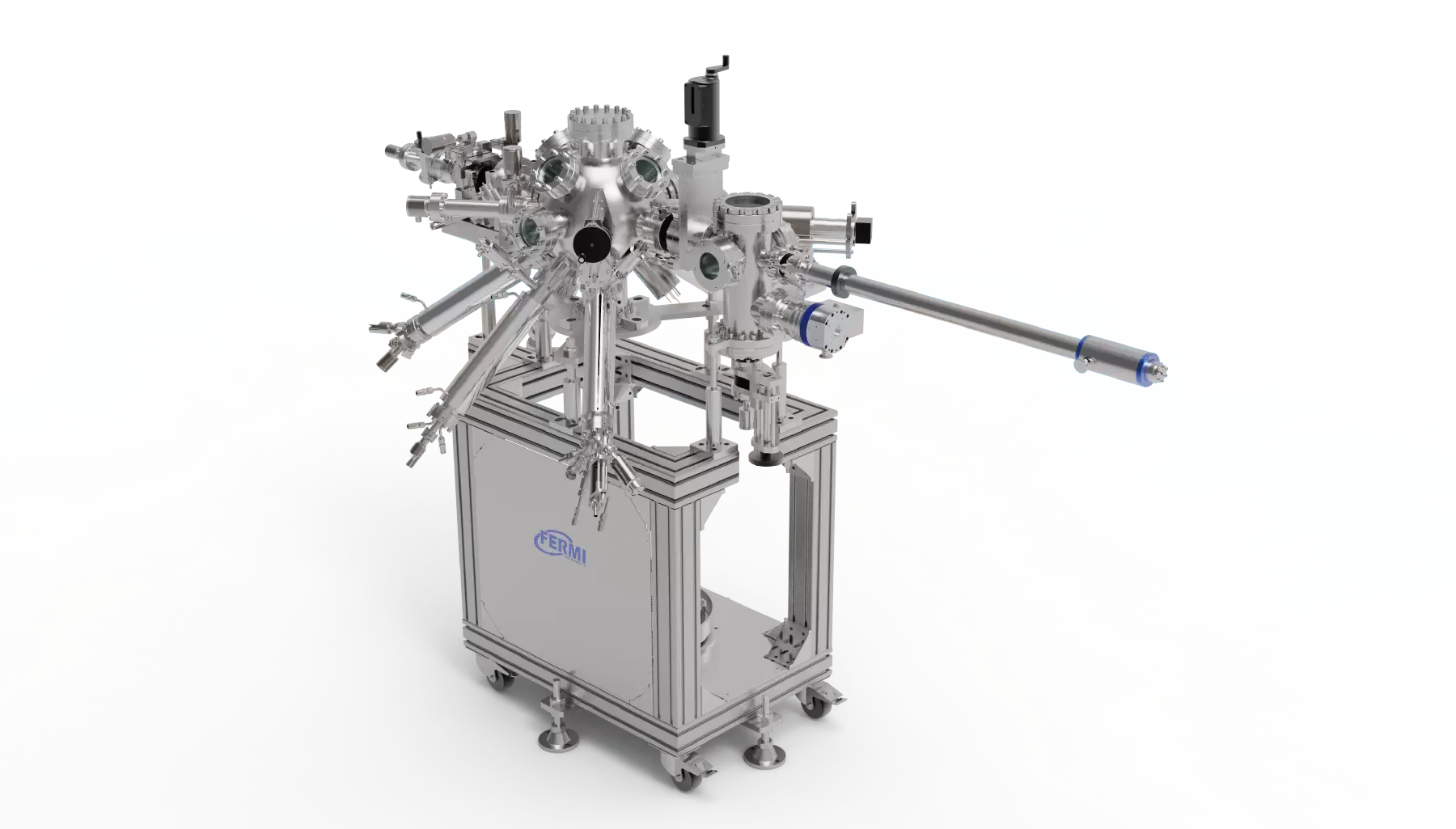

Sphere 300 mainly uses a spherical 316 stainless steel cavity processed by argon arc welding, with a diameter of 300mm, and can accommodate up to 5 evaporation sources. The Sphere 300 growth chamber is reserved with multiple flange ports, which have complete functions and can achieve RHEED in-situ characterization. The system is suitable for the growth of small-sized (matching flag shaped sample holders) samples and is very suitable for scientific research users to prepare high-quality thin films.